Glass used to be the method most used to cover greenhouses. Now it has been replaced by plastics, mainly acrylic (plexiglass) and polycarbonate (Lexan) sheets.

Quick facts about acrylic and polycarbonate

- Acrylic is 17 times more resistant to impacts than glass and weighs half as much. Polycarbonate is 250 times more resistant to impacts compared to glass and is half its weight

- Acrylic is the less expensive option and clearer than glass; more rigid than polycarbonate, easy to scratch and tends to be more affected by chemicals. Polycarbonate is more flexible, more resistant to chemicals and abrasion, but it costs twice as much as acrylic.

- Both polycarbonate and acrylic have a light transmittance ranging from 88% to 92% of glass (acrylic is clearer than glass and transmits more light than polycarbonate).

Both glass alternatives have one factor in common: they will shrink as the temperature drops

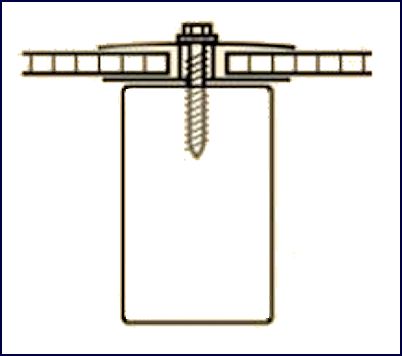

The shrink rate of either material varies on factors such as the manufacturing process and raw materials used, but for a typical greenhouse, the shrinkage will be noticeable. To remedy this, the solution is to use “channels” to hold the panels in place while solving the shrinking issue.

How channels work

Panels are slipped in between 2 channels. The fit is snug with just a slight amount of wiggle room. In situations where the temperature is low, such as in winter, the long lips of the channel ensure that the panel will not fall. The result is that there is no stress on the panel and the greenhouse remains watertight.

When glazing a geodesic greenhouse, H channels are on each side of every panel and each side will need to be shorter to accommodate the space used for the channel.

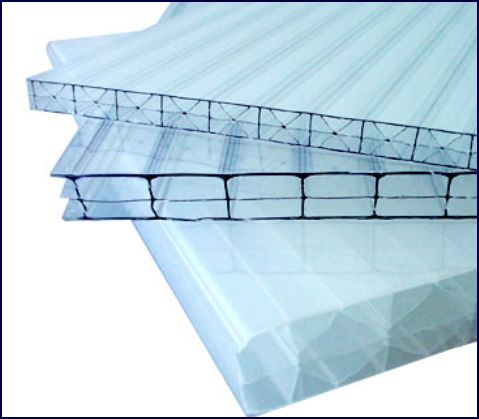

The more layers a polycarbonate panel has, the greater the insulating value it will have. It is common to see double layer panels for greenhouses.

For more information on polycarbonate for greenhouses, click here.