Geodesic timber struts: cutting

Cutting timber struts

For timber domes, you can follow the classic method of cutting the angle at the tip of the strut and join them using a hub (many smaller domes will use a piece of pipe to attach struts together), or making individual triangles. To build a geodesic dome home with standalone triangles is by far the strongest way to go, and easier to assemble each piece. But it will require cuts on 2 planes.

By this we mean to cut in 2 directions. A miter saw can be set to do this, although a radial arm saw is more precise and stable. Often the deciding factor will be how much of an angle a saw can cut. This is a critical factor to consider. Look at the saw’s specifications to confirm.

You can also use a worm saw. It is recommended to make strut cuts with precision to a 1/10th of a degree. Radial arm saws can have that precision. Miter and worm saws, not always.

And if your dome is made from individual triangles, you will need to make another type of cut along the length of each strut (called a bevel). By triangle construction we mean a geodesic dome which is made in a modular fashion: Each triangle is a “face” made up of 3 struts.

In short: 2 cuts for each strut end, bevel cut along the length of the strut if you build from triangles.

Equipment to cut geodesic dome struts

|

|

|

Radial arm saw |

Miter saw |

Worm saw |

Any of the above can cut dome struts for your project. Ideally a radial arm saw is preferred because it can make very precise cuts, even compound cuts for each strut. A miter saw with the stops removed will also do a good job. For the more advanced carpenters a worm saw will work as well.Whichever you use, precision is key with timber struts.

Types of hub configurations

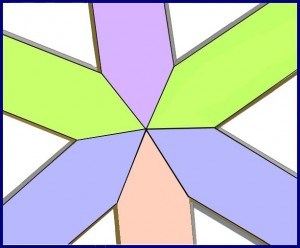

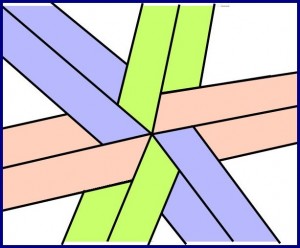

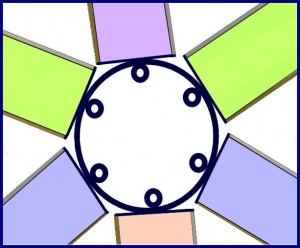

|

|

|

| Struts are all joined together without a hub system | This design uses dual layer struts | This design requires only one cut at each strut end (no compound cut) |

At the bottom of the page you can view a video of how to cut a geodesic strut with a compound angle. You can also visit this website for a very detailed presentation on making timber struts.

How strut cuts are made

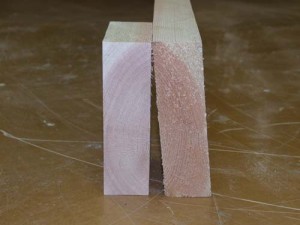

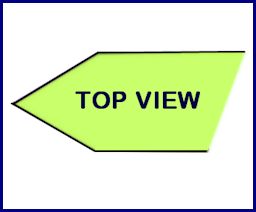

|

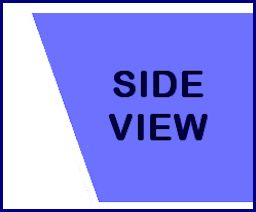

|

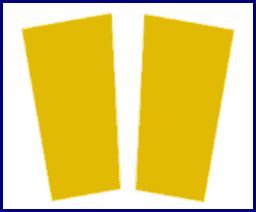

|

| Two cuts are made at the tip of each strut. You divide 360 degrees by the number of struts X 2 (2 angles) on each strut. | The side view shows another angle to cut. This one is the same as what you get when using a geodesic calculator | Making a geodesic dome from individual triangles requires a cut or bevel along the length of each strut side to fit with adjoining ones. |

For those who want to see actual projects from planning, workshop tasks to covering , the following link is a detailed example (click on the image below to visit the site).