Structures & Coverings

Many advances in greenhouse materials and designs have occurred in the last few years. Traditionally, greenhouses were made of glass and all had a similar structure. Today, however, a great variety exists, and the materials chosen depend on production goals and financial constraints.

Types of Greenhouses

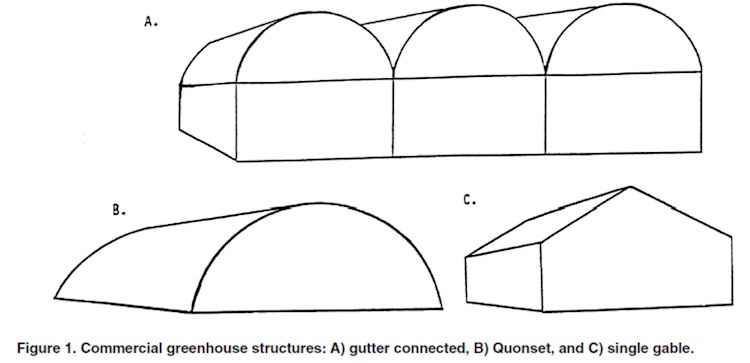

Freestanding (single) or ridge and furrow (gutter connected) greenhouses are two common styles of commercial greenhouses. The freestanding style is often a Quonset, which will accommodate many growing situations but presents height restrictions near the side walls. Another freestanding style is the single gable greenhouse and its many variations.

The ridge and furrow or gutter connected greenhouses are joined at the eave by a common gutter. When several of these buildings are joined they are often referred to as a greenhouse range (Figure 1).

Foundations

The foundation must resist overturning and vertical pressure from structural loads and snow, and should extend below the frost line. Concrete is the most appropriate material for permanent structures. A 2,500 PSI or greater mix should be chosen when ready-mix concrete is used.

Unless the grower is constructing a greenhouse without the use of a manufacturer, specific recommendations are usually provided for adequate durability of the foundation. The foundation stage of construction is critical and consulting with appropriate personnel, such as experienced builders, is highly recommended.

Structural Components

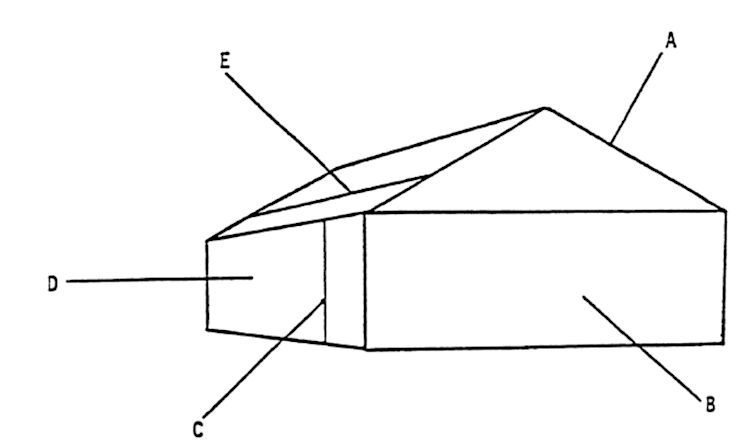

The major vertical support of greenhouses is provided by rafters placed on two to four foot centers, depending on the strength needed. Depending on the width of the structure, truss or curved arch type rafters are used.

Purlins are arranged horizontally and connect the rafters. Four to eight foot spacings are used depending on the size of the greenhouse. Cross ties are also used in certain houses. In areas where high winds occur, purlins are important in maintaining structural integrity of the greenhouse.

Side posts and columns are vertical supports that dictate the height of the production area. These range from one to ten feet in height and should be given serious consideration since they directly influence efficiency (Figure 2). Quonset style greenhouses are an example of a structure with low side walls, making it difficult for laborers to work or grow plants in that reduced area (Figure 1).

Framing Materials

Aluminum is the most economical material for constructing the greenhouse frame. It can be shaped as needed to form various structural components of the greenhouse and needs no maintenance after installation. Aluminium framing also has the longest life span and allows for light reflectance.

Steel is commonly used but must be painted or galvanized to resist high moisture conditions within the greenhouse. Steel needs more maintenance than aluminum and is heavier, requiring additional support.

Wood was once a common framing material, but it has steadily lost popularity for a number of reasons. The main disadvantage of wood is that it deteriorates over time. If wood is desired, pressure treated lumber should be purchased and then treated with commercially available coatings. Avoid PENTA and creosote since they liberate fumes that are harmful to plants.

Coverings

Glass allows maximum light transmission in greenhouse production. Despite this, there are several disadvantages to consider. Glass is expensive and, because it is fragile, has to be replaced more often than many other materials on the market today. Also, consider that when using glass, the cost of structural components will be expensive because of the added weight which must be supported. When glass is desired, check with the manufacturer for double and triple strength ratings available. Also, “hammered” or “frosted” panes will distribute incoming light better by dispersing the rays, resulting in fewer shadows. This type of glass is not transparent from the outside, which can be an added security benefit in certain situations.

A double layer of polyethylene, inflated with air, is another option to consider for covering the greenhouse. One advantage of using this material is that it is relatively inexpensive. Materials have greatly improved and some manufacturers guarantee their materials for up to four years. Look for ultraviolet stabilized products that are slower to yellow and crack. Single and triple layer polyethylene coverings are used less commonly. Replacement of a polyethylene covering as a result of wind, hail, or solar damage will be more frequent than any other covering, but the low investment and the need for less structural components make it a material to consider when a temporary greenhouse is desired. Two additional products, available commercially, to extend the life of a polyethylene house are poly patch and anti-drip material. The anti-drip material reduces condensation that can harm plants growing below. Condensation should also be controlled to prevent lowered light transmission, especially during the winter months when low light levels may limit plant growth.

Fiberglass is another material that has gained popularity over glass. It is very durable, rigid, and available in various light transmission levels. Ultraviolet light will cause fiberglass to deteriorate in a few years from swelling and fraying of the fibers. This in turn quickly leads to lowered light transmission to the plants. However, there are products now available that will help reduce the fraying. These coatings should be applied prior to damage to the fiberglass. Although the life span of fiberglass can be as short as five years, choosing higher grade products and applying a coating may result in a twenty year life span.

Polycarbonate is one of the newest materials available and is still being evaluated. This material is rigid but also flexible enough to be used in a Quonset style greenhouse. Although the initial cost of polycarbonate is high, a ten to 15 year life span can be expected. Polycarbonate can be purchased in double and triple walled forms which are highly impact resistant.

Acrylic is also new and expensive but it has a minimum ten year warranty from some manufacturers. Although many advantages exist such as high light transmittance, high impact resistance, and great strength, costs have proven prohibitive in most cases.

Figure 2. Basic structural components of a greenhouse: A) rafter, B) end wall, C) side posts, D) side wall, and E) purlin.

Remember to check with the covering manufacturer for several factors.

1. Combustibility – Some materials may result in lower insurance premiums if they are fire retardant. Other materials are highly flammable, such as fiberglass reinforced panels (FRP), and that must be considered. Fire retardant FRP panels can be purchased.

2. Durability – Not only will this differ among materials, but also will be determined by whether they are one, two, or three ply.

3. Insulation – Note insulation “R” factor and compare for fuel savings. Heat retention from highest to lowest:

Acrylic (double layer)

Polycarbonate (double layer)

Glass (double layer)

Polyethylene (double layer)

Fiberglass

Keep in mind that this is relative to the number and thickness of layers used.

4. Life span

5. Care – Maintenance may be required to realize life span claims from manufacturer.

6. Guarantee – Read warranties carefully as most will be limited.

Shading Compounds

During the summer months the solar radiation in Oklahoma is too intense for many crops to be grown to acceptable quality. Shading is necessary to make greenhouses usable and to prevent overtaxing the cooling and ventilation systems.

Many commercial shading compounds can be applied in the spring and removed as fall approaches. Instructions are provided to reach the desired percentage of radiation blockage. Liquid formulas are commonly used for glass and sometimes fiberglass. However, frayed fiberglass may absorb the liquid, making it impossible to remove when maximum solar radiation is again needed. Another alternative is to use shade cloth. It can be purchased for the percent of solar radiation reduction desired, depending on the crops grown.

Division of Agricultural Sciences and Natural Resources • Oklahoma State University

Michael A. Schnelle

Assistant Professor

Extension Ornamentals/Floriculture Specialist

John M. Dole

Assistant Professor

Floriculture