Cover Templates for 3v 5/9 Geodesic Dome

Often the most difficult step in completing a geodesic dome, whether made from metal tubing, conduit or timber, is the cover. This is because the shapes are not conventional; they are triangles, hexagons, pentagons.

So, Domerama decided to make things simpler:

- We took the most popular geodesic dome frequency, the 3V

- We used the Kruschke version of the 3v because it is flat at the base (unlike the standard class I 3v 3/8 or 5/8)

- Lastly we decided on a 5/9 design (a little more than a half sphere).

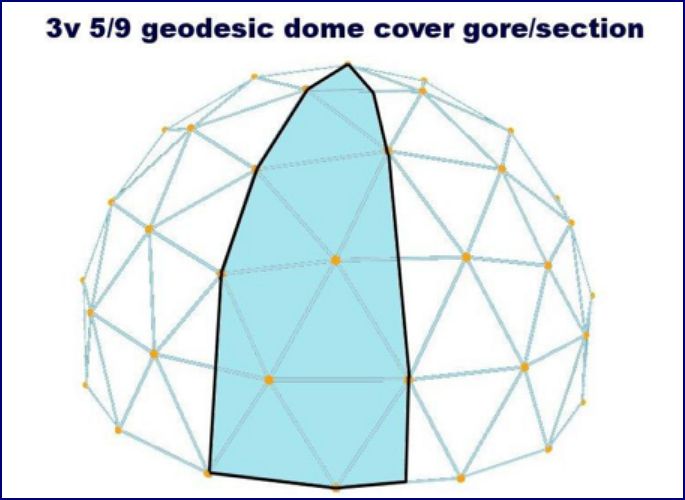

A geodesic dome consists of 5 identical sections one beside the other. This simplifies making a cover pattern because of the repetitive nature. Next we had to take into consideration that the average fabric roll width is about 60 inches or 150cm.

This led us to create a pattern consisting of 10 identical sections to cover the entire dome. A 16-foot (5 meter) dome can be made from 10 sections of a standard width roll, but anything wider than this you will need to pre-sew sections which will then be sewn and then again cut to make a large cover and other factors.

A good fit depends on many factors

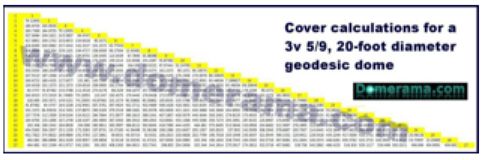

The calculations offered are very precise, maybe even too precise for some. There may be a slight tension or looseness of the cover on the geodesic dome due to the type of fabric, the expansion or contraction depending on weather conditions among other factors. This is why the last section of the cover will be one where adjustments are made.

This is a double pattern (2 sections together)

This is especially true when covering a metal tubing or conduit dome: these are made to be assembled then taken down and relocated. But in the case of a timber dome you can nail, screw, glue, staple a covering to the structure, your struts are wider. And in the case of timber domes the cover often does not need to be assembled into a single piece.

A gymnasium makes geodesic dome assembly easier!

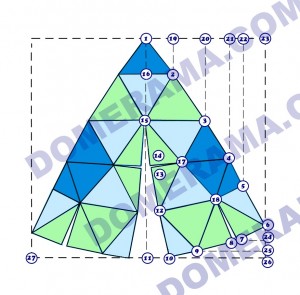

OK, so you may not have a gymnasium to aseemble the dome sections together, and you don’t really need one. In the two images below someone used the calculations to make a 45-foot (15 meter) dome. You can see where the slits in the sections were made. These insure that the cover will fit on a curved surface.

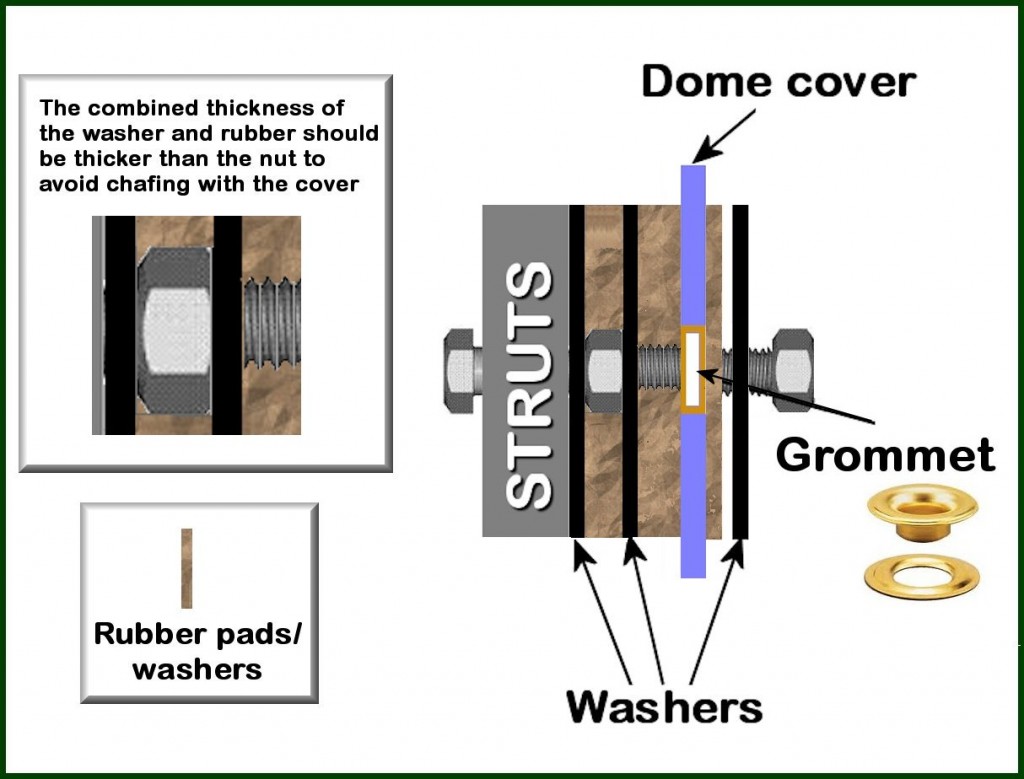

A different way to attach your cover to the geodesic dome

Also keep in mind the hubs can serve as attachment points for your cover. This way the cover moves less, will have more tension and looks better. You can punch a hole where the bolt is and add a grommet with a piece of extra fabric to strengthen the grommet. To avoid water leakage use rubber pads under and over the grommet.

To hold the grommet in place, you need to insert the bolt from the inside so the tip sticks out on the outside. Look at the image below.

How difficult is it to cut the sections?

It is quite simple to cut the sections, and with the help of a distance grid which looks like those distance tables on maps, you can confirm all important dimensions before cutting any fabric.

Another point to mention is how securing the cover to the dome will be crucial in how well both fit together. A cover that is evenly stretched over a dome at multiple points will result in a better fit and more resistant to winds, rains and other conditions.

We offer the calculations for the following:

Cover template for a 10-foot, 3v, 5/9 Geodesic dome